The IDEAL First 260 traveler

As the skipper of a boat that races a lot of windward/leeward courses, I have long thought that the optional(!) First 260 traveler was less than ideal. Too short, too low, too hard to work. So I set out trying to work on a better solution.

The trick was that the placement of the cockpit lockers made a wide bar problematic. But a wider, higher bar was the ideal solution, even if it meant some compromises in other areas. The first clue came when I found a picture (below) of a First 260 in France that had been modified with a cockpit-wide traveler. This is interesting because it has the bar mounted in the ONE possible place where it does not interfere with either the lockers or the wooden seat rails, and is still under the boom. Ideally, it is exactly at boom end. I had thought of this as an option, but it took seeing it done once to commit me to action. It has the effect of shrinking the driver area by about 4 inches. The tiller clearly had to be cut shorter, but the bar looked good. Some work would have to be done, but that was all part of the game!

I was not able to find or contact this owner, so I had to set out on my own. The questions were:

1) what traveler system to use?

2) how to mount it level over the seats?

3) how to support it over the cockpit well?

4) what are the ramifications for the tiller?

The first question was the bar. Knowing the the cockpit at that area was just over 1.5M wide, the Lewmar Traveler Sz1 kit (with a 1.5M bar) might be ideal. In the USA this kit runs about US$380. The size of the 260 mainsail with end-boom sheeting was well inside the operational range of this kit.

This unit is well regarded and is designed to be used on boats up to 35 feet in length. The install guide says that you can use either M6 or 1/4in bolts, but sadly I found that the heads of 1/4in bolts would not fit into the track groove.

There were two installation issues on the First 260.

1) Reinforcing the bar under the span of the cockpit well.

2) Leveling the bar over the sloped seats.

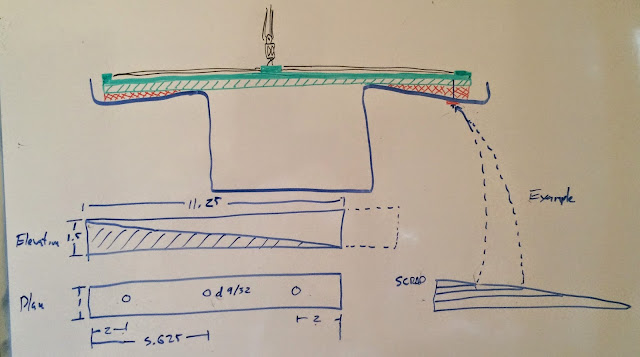

For problem #1, I chose to mount the bar over a 1 inch x 1 inch stainless steel tube with 1/8 inch thick walls. This is the exact width of the bar itself. From this point I will use both imperial and metric units, readers might have to convert to metric for local values. I then used an on-line tool to calculate max defection over 28 inches (cockpit well width) and the amount with a 250 lb load (up or down) was minimal. This meant that a full load on the main, or a heavy crew member standing on it would be a non-issue.

For problem #2, I has two ramps of UHMWP (Ultra High Molecular Weight Plastic) made. This is sold under the brand name 'Starboard' in the USA. With ramp of 1.5 inch high over a 11.25 inch run, it would match the seat perfectly.

As mentioned above, metric M6 bolts were used to secure the track to the SS tube, through the wedges and through the deck. The longest were 120MM. The shortest were 40mm. They were placed (per Lewmar specs) at 4 inch centers. Three bolts were used on each seat; 5 were used over the companionway span. The holes in the seat were drilled oversized and filled with epoxy, then redrilled at M6 size. I recommend drilling the holes in the SS tube FIRST, and then using that as a jig to drill through the UHMWP and deck in one go. I did this in reverse order, and had to deal with the unnecessary complication of having to line up the holes exactly when I drilled the stainless.

The resulting traveler is VERY solid. I marked the bar with 8 positions to allow re-creation of windward setting on each tack. The traveler line is a single 1/4 inch length of NEL Stayset double braid that allows you to release the leeward side when you pull the car upwards. the 4:1 purchase makes moving the car easy under any load.

The final cockpit solution. The tiller has to be cut about 2 inches to allow the mainsheet block to pass by unobstructed. On our boat this is not an issue as we always use a Spinlock tiller extender and the cut was in front of this attachment point. As such it did not change the effective leverage we are used to.

As a driver, the slight reduction of my working area is totally worth it. I have to tilt the tiller upward to tack, but I did that with the old traveler anyway. The team in front of the bar now has more room; the main trimmer in particular has much more room. And the 2x additional range of the bar and the 2x increase in purchase vs the old traveler makes this the best modification we have made to the boat. Perhaps not an ideal cruiser solution, but if you are interested in maximum performance from your 260, this is the way to go. Combine with the new 3:1/6:1 two-speed mainsheet, perfection!

The trick was that the placement of the cockpit lockers made a wide bar problematic. But a wider, higher bar was the ideal solution, even if it meant some compromises in other areas. The first clue came when I found a picture (below) of a First 260 in France that had been modified with a cockpit-wide traveler. This is interesting because it has the bar mounted in the ONE possible place where it does not interfere with either the lockers or the wooden seat rails, and is still under the boom. Ideally, it is exactly at boom end. I had thought of this as an option, but it took seeing it done once to commit me to action. It has the effect of shrinking the driver area by about 4 inches. The tiller clearly had to be cut shorter, but the bar looked good. Some work would have to be done, but that was all part of the game!

I was not able to find or contact this owner, so I had to set out on my own. The questions were:

1) what traveler system to use?

2) how to mount it level over the seats?

3) how to support it over the cockpit well?

4) what are the ramifications for the tiller?

The first question was the bar. Knowing the the cockpit at that area was just over 1.5M wide, the Lewmar Traveler Sz1 kit (with a 1.5M bar) might be ideal. In the USA this kit runs about US$380. The size of the 260 mainsail with end-boom sheeting was well inside the operational range of this kit.

This unit is well regarded and is designed to be used on boats up to 35 feet in length. The install guide says that you can use either M6 or 1/4in bolts, but sadly I found that the heads of 1/4in bolts would not fit into the track groove.

There were two installation issues on the First 260.

1) Reinforcing the bar under the span of the cockpit well.

2) Leveling the bar over the sloped seats.

For problem #1, I chose to mount the bar over a 1 inch x 1 inch stainless steel tube with 1/8 inch thick walls. This is the exact width of the bar itself. From this point I will use both imperial and metric units, readers might have to convert to metric for local values. I then used an on-line tool to calculate max defection over 28 inches (cockpit well width) and the amount with a 250 lb load (up or down) was minimal. This meant that a full load on the main, or a heavy crew member standing on it would be a non-issue.

For problem #2, I has two ramps of UHMWP (Ultra High Molecular Weight Plastic) made. This is sold under the brand name 'Starboard' in the USA. With ramp of 1.5 inch high over a 11.25 inch run, it would match the seat perfectly.

As mentioned above, metric M6 bolts were used to secure the track to the SS tube, through the wedges and through the deck. The longest were 120MM. The shortest were 40mm. They were placed (per Lewmar specs) at 4 inch centers. Three bolts were used on each seat; 5 were used over the companionway span. The holes in the seat were drilled oversized and filled with epoxy, then redrilled at M6 size. I recommend drilling the holes in the SS tube FIRST, and then using that as a jig to drill through the UHMWP and deck in one go. I did this in reverse order, and had to deal with the unnecessary complication of having to line up the holes exactly when I drilled the stainless.

The resulting traveler is VERY solid. I marked the bar with 8 positions to allow re-creation of windward setting on each tack. The traveler line is a single 1/4 inch length of NEL Stayset double braid that allows you to release the leeward side when you pull the car upwards. the 4:1 purchase makes moving the car easy under any load.

The final cockpit solution. The tiller has to be cut about 2 inches to allow the mainsheet block to pass by unobstructed. On our boat this is not an issue as we always use a Spinlock tiller extender and the cut was in front of this attachment point. As such it did not change the effective leverage we are used to.

As a driver, the slight reduction of my working area is totally worth it. I have to tilt the tiller upward to tack, but I did that with the old traveler anyway. The team in front of the bar now has more room; the main trimmer in particular has much more room. And the 2x additional range of the bar and the 2x increase in purchase vs the old traveler makes this the best modification we have made to the boat. Perhaps not an ideal cruiser solution, but if you are interested in maximum performance from your 260, this is the way to go. Combine with the new 3:1/6:1 two-speed mainsheet, perfection!

Well done, and well thought out. I know Lewmar sells beam for spanning cockpits and the like, but it doesn't come with the kit. I rather like the stainless bar.

ReplyDeletePeter in Canada

Yes it works well!

Delete